THERMAL AGEING IS NOT A MAGIC TRICK

Quality means everything

Tonewood quality should mean everything to you as a player in the same way as it does for me. Why? Because that is the very key element dictating whether a guitar has the potential – the genes – to become a great musical instrument.

Can’t make bad wood into good

Thermally aged tonewood is not a magic trick – the thermal ageing process doesn’t change bad wood into good. But it is the best possible way to make sure my tonewood is all game to begin the transformation into a great guitar.

I share with you what I know

In this article I share with you what I know of thermally aged tonewood. The process was developed in Finland originally for construction and furniture industry in the early 1990’s – developed further and adapted into musical instrument wood in the 1990’s – eventually becoming popular in the rest of the world, too.

These days thermally aged tonewood has many nicknames: torrefied, roasted, baked or caramelized wood being the most common trade name variations recently taken into use, as thermally aged tonewood has finally gained success also in North America.

THE HISTORY OF THERMALLY AGED TONEWOOD

The inventive spirit

I’m not perhaps the best expert on historic tidbits of thermally aged tonewood development, but this is the short version as I’ve learned it from my teacher Rauno Nieminen, one of the original developers of thermally aged tonewood.

There was this Fire Chief, Osmo Savolainen, of a little town in Finland, who knew a lot about fire. He also knew a lot about what water does to fire. And he knew what fire does to wood. It is the classic story of creative / inventive spirit: “I wonder what would happen, if I connect these natural phenomena…”.

Fixing the children’s playgrounds

Osmo came up with an idea to treat wood with heat to make it more resistant against decaying, mold and fungus. His original target was to create an environmentally friendly, non-poisonous material for children’s outdoor playground toys.

Photo: Visiting the inventor of the original thermal treatment Osmo Savolainen. From left: Juha Lottonen, Osmo Savolainen, Pertti Nieminen, Rauno Nieminen, Juha Ruokangas.

WHAT HAS SAUNA TO DO WITH THERMAL AGEING?

A scary piece of equipment…

So, Osmo placed wooden planks into a container (a scary piece of equipment, that first thermo treatment facility!), which was heated up to a temperature that would normally set the wood on fire. Osmo, however, injected water vapor to the container, raising the relative humidity up to 100%, and preventing the wood from igniting. The basic idea could be compared to steam boiling. Or Finnish sauna…

It worked!

Osmo’s idea worked! The wood didn’t burn – instead it came out different from what it had been before the treatment – and according to Osmo’s experiments, he had indeed reached his goal and developed a viable substitute for poisonous, impregnated wood.

The big fish eats the small fish!

Osmo presented the invention to an organisation called the VTT (Valtion Teknillinen Tutkimuskeskus – Technical Research Centre of Finland) – who got interested and started its own research to find out more about what happens in the process.

Don’t ask me how exactly it happened, but at the end of the day, the VTT went on to patent the new groundbreaking technology to its own name, dropping Osmo out of the picture. The big fish ate the small fish! Sad… yet not the first (or the last) time this happens.

In the wee small hours

As I’m writing this article (in the wee small hours, November 28, 2016), all thermally aged tonewood (both in Europe and North America) that ever was or is commercially available at this point of time, is based on this technology patented by VTT.

Now, here’s an important reminder: The technology patented by VTT was not invented for musical instruments, but to produce environmentally friendly substitute for chemically impregnated wood in outdoor applications.

The story continues, read on…

THE BIG PICTURE STARTS TO CRYSTALLIZE

17th century violins and thermal ageing

Somewhere down the road, professor Pertti Nieminen (who was involved earlier in the VTT funded thermal treatment research project) showed Rauno an electronic microscope image of thermo treated spruce – and for Rauno, this rang a bell. He remembered seeing something very similar in Strad magazine – an electronic microscope scan of 17th century violin top…

It began in 1996

Pertti and Rauno summoned a special project to map out whether this thermal treatment method could be something meaningful for tonewood. It started in 1996, lead by the Ikaalinen College of Arts and Design (Rauno Nieminen, Lutherie Dept.), Suomen Ekopuu (Osmo Savolainen’s company), Tampere Technical University (Pertti Nieminen) in the lead – and a bunch of musical instrument makers – guitars, violins, church organs and more.

Scientific research for years to come

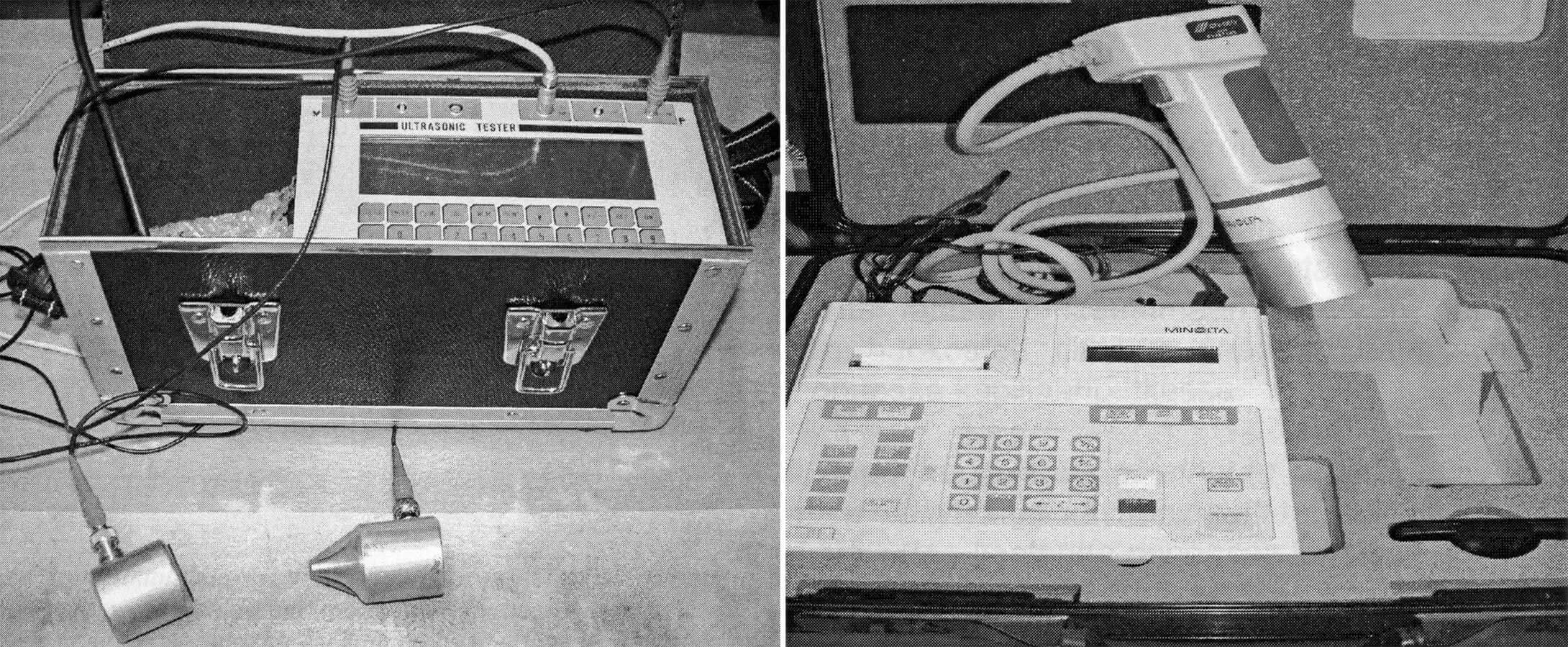

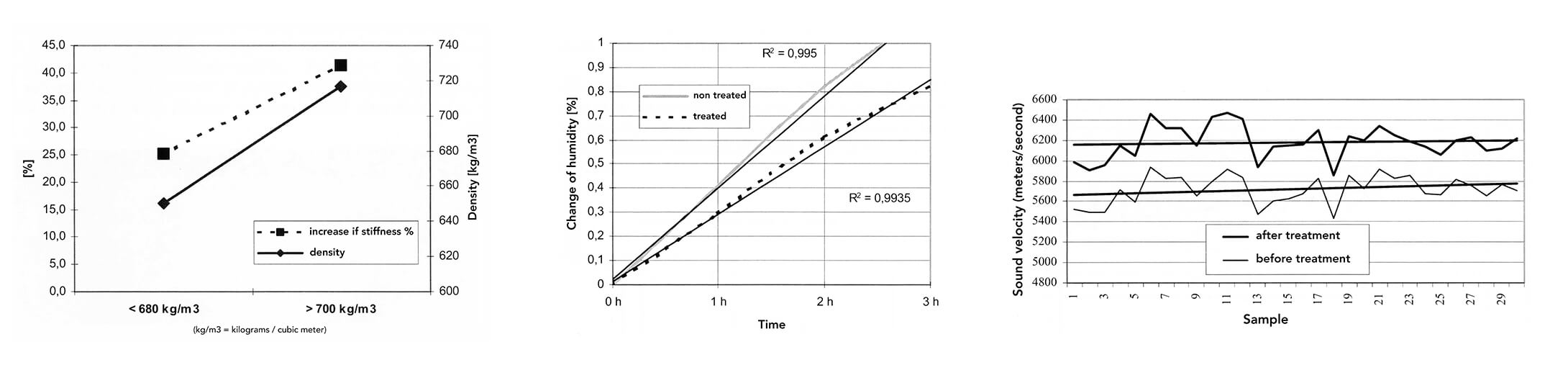

The scientific research project went on for years, changing format and funding channels. I hopped in to the project in 1999. Each company sent materials to be thermally treated, and every piece of wood went through a complex test routine before and after the treatment – microscopic cell structure study, sound velocity testing, bend-strength, absorption capacity measurements, workability tests, and experimental (subjective) tap tone tests by the musical instrument makers.

A turn of events

Each of us luthiers made musical instruments using the thermally treated materials. And slowly, through all the testing, the big picture started to crystallize. There was indeed something beneficial to this process. As the study progressed, it led us all into a new direction, as compared to the technology patented by VTT. Pertti, Rauno and the other researchers had realized, that in order to use this method for tonewood, the treatment temperatures must be much lower than they originally were set.

THE MAJOR BREAKTHROUGH NOBODY KNOWS ABOUT

Heavy weight data

The project came to its end by the turn of millennium, and the official 75-page report was eventually published in 2002. It was a heavy weight research with tons of data. In terms of using thermal treatment for musical instrument wood, this research was nothing short of a major breakthrough.

Thermally treated – or thermally aged?

But – all this knowledge remained sort of a secret among the Finnish musical instrument makers that had participated in the project. Why so? Not because we chose to keep it to ourselves. Not because there would be a patent – there never was and still isn’t a patent for thermally aged tonewood. Remember, this method differs significantly from the VTT patent.

Digital publication – what’s that?

No… we didn’t consciously keep this hidden from the world. It’s just that… the study was published only in Finnish language! And to make things even more challenging – it was never published in digital format – not even in Finnish language! (This has changed since the article was written – read on so you’ll find out how!)

The first on the market

So there I was, a young guitar maker, preparing for my first international guitar trade fair held in Frankfurt in year 2000. I had this amazing invention – Thermally Aged Tonewood – in my hands. I was the first guy entering the international market with electric guitars carved out of thermally aged tonewood. You can’t imagine – I was so excited!

Scientists in white coats selling guitars

And I was such a hopeless rookie. I was giving flyers to all visitors – and I talked and talked and talked… I learned that year at Frankfurt Musikmesse the hard way, that men in white coats showing scientific evidence – no matter how heavy weight – just can not convince the guitar buyers. That’s just not how the world works.

One by one

Oh well – I have learned my lesson. I’ve worked hard ever since then to educate and convince players, one by one, about this breakthrough technology. Eventually things have worked out fine, as our customers have noticed through their own experience that this is the real thing.

THE BUTTERFLY EFFECT

The chain reaction starts

For a long time it felt like we were the only ones pushing on with it. One of the turning points took place in January 2006, when the ToneQuest Report magazine published an article about us and thermally aged tonewood. That article aroused a lot of discussion and interest in the North America towards the method, and I’d like to think that this very article might have been even the nudge (ref. ‘The Butterfly Effect“) that started the chain reaction leading Music Man and eventually so many other big and small companies to adapt thermally aged tonewood into their production.

Will the ship turn?

The fact that more or less all of them are using the “VTT era parameters” is most likely a passing phase – eventually (after a lot more talking!) the ship will turn and the “right kind” of thermally aged tonewood will take over and become the standard technology.

BETTER GUITARS, EASIER LIFE

Untreated vs. treated

So – what exactly does the thermal ageing process do to tonewood? During the research in Finland, comparisons were made between untreated, treated and some hundreds of years old naturally aged pieces of wood.

The main species studied were spruce, alder, birch and maple. Some tests were done with spanish cedar, mahogany, rosewood and ebony – but more studies would be required to say much about them, as the samples we treated developed severe cracking in the early tests.

This is what happens

1) Stability improves

2) ability to absorb moisture decreases

3) cell walls harden

4) resins crystallize (and partly vapourize)

5) rigidity (bend strength) increases

6) pores clean up

7) sound velocity increases

8) colour deepens

9) weight drops

The process doesn’t change bad wood into good wood, but it does make the good stuff even better. The bottom line is this: Thermal ageing changes wood in the same way as decades of natural ageing does, period.

In other words – when done right, thermal ageing doesn’t do anything unnatural to the wood.

It makes my life easier

For me, it is simply a practical improvement. I’ve been enthusiastic about it, because it makes my guitars better – and in return, it makes my life easier.

WHY TO USE THERMALLY AGED TONEWOOD?

Let me tell you the story how our Steam bass model came to exist. Not sidetracking here – this is the perfect pragmatic example why thermal ageing makes sense.

From guitars to basses

I started out as a guitar maker, and making basses came into the picture much later. Ever since I started using thermally aged tonewood in my guitars, however, I was thinking that it would be very interesting to make a bass out of it. This was mainly because of the improved rigidity thermal ageing does to wood.

What is a ”dead spot” on fretboard?

Especially the neck can often be tracked down as the cause of so called “dead spots”. They are notes that decay much faster than the rest of the notes on the fretboard. There are such notes in every instrument that decay a bit faster than other notes, but usually you call a note dead spot at the point when it gets really noticeable. Guitars can have this too, but in bass guitars the phenomenon can be much more dramatic.

Wait… this shouldn’t be possible!

With thermally aged tonewood, I felt that I might be able to work miracles and keep these problematic peak resonances in control better. Later on, when my first bass prototype was being tested in Germany by my friend Markus Setzer, one of his first comments was: “All the notes sustain beautifully. It shouldn’t be possible in a bolt-on neck bass!”. I was thrilled. I knew I was onto something extraordinary.

SHARING KNOWLEDGE TO THE FAMILY OF GUITAR MAKERS

What is the difference?

A lot of people keep asking me what is the difference between the commercially available, more dramatic (caramelized – torrefied – baked – roasted) treatment and the milder ageing process we use.

Well, the main difference is this: When the wood is “overcooked”, the changes that occur are something else than what natural ageing does. The color changes a lot – the cells partially break – the sound velocity decreases – the wood becomes fragile and difficult to work with. The stability of “overdone” wood is excellent, but nobody really knows how such wood will mature in time, hence the fragility and partially broken cellular structure.

The truth, as I’ve experienced it

My point in sharing this information is absolutely not to badmouth companies using baked wood. My sole intention is to share knowledge. That’s what I’ve been doing the past 20 some years – so that more luthiers would gain from it.

So there you have it, the truth, as I’ve experienced it through my involvement in the development process of thermally aged tonewood, and through my own guitars that all have had thermally aged tonewood in them since 1999.

JUNE 2020 UPDATE

I became involved in a new project related to Thermally Aged Tonewood some years ago. This project, Suomisoitin Suomipuusta, was funded by the Finnish Cultural Foundation and organized by MES Foundation. The purpose of this new endeavour was to update those old Technical University papers with all the data accumulated during the past decades through the Finnish musical instrument makers hands-on experience in using Thermally Aged Tonewood materials.

Make your own Thermally Aged Tonewood?

We also set a goal at solving one way or the other the problem of the scarce availability of Thermally Aged materials. After pondering the various possibilities how to do this, we figured that since every luthier has his/her own favourite species of tonewood and different needs regarding quantities and plank sizes to be Thermally Aged, the best possible solution would be to instruct luthiers to make their own Thermal Ageing ovens on a reasonable budget.

Hats off!

I want to thank Hannu Saha (MES), the coordinator of our task force. The biggest work was done by Rauno Nieminen, the grand old master of Finnish musical instrument making – hats off! I want to also thank the rest of our work group: Pertti Nieminen and Juha Lottonen. A big thank you also to Jukka Ollikka – without his invaluable input our job to come up with a DIY Thermal Ageing oven would have been much harder.

Sharing is caring

The best part of our project comes here: The Finnish knowledge accumulated since the 199o’s about Thermally Aged Tonewood is finally available online both in Finnish and English languages, complete with instructions how to make your own Thermal Ageing oven! Here you go – download the pdf:s here:

LECTURE AT HOLY GRAIL

I did a lecture about thermally aged tonewood at The Holy Grail Guitar Show 2014. This recording was done privately by us, and wasn’t initially intended to public use. The sound quality is what it is, but here you go. Might be an interesting splash for the true aged tonewood nerds.

BOTTOM LINE

Thermally Aged Tonewood is identical with wood that has been seasoned for decades. When done the right way, the thermal ageing process has only positive effects to the wood.

– Juha Ruokangas